December 31, 202

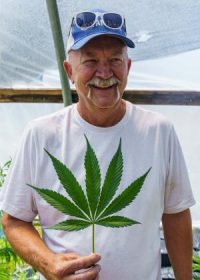

Papa G’s Organic Hemp Farm worked with Indiana NRCS to add a needed high tunnel to their farm, improving the quality of their plants, extending their growing season and helping their farm to grow.

Jeffery Garland had spent years living in Los Angeles and then Colorado building a successful content creation business. He worked on tv and movie sets taking photographs, filmed commercials and built a network of contacts across multiple industries.

Then, like so many others, his life came to a screeching halt in March 2020. The COVID-19 pandemic began raging throughout the world and the industries he relied on shut down. So, he picked up the phone, called his dad and pitched him on a radical idea.

“I said, ‘Dad, have you ever thought about maybe growing hemp,’†Jeffery recalled of the conversation that led to the creation of Papa G’s Organic Hemp.

Even while building a successful photography and cinematography business, Jeffery had always found time to garden. It was a passion he developed as a child working in his grandparents’ garden and from his dad Jeff, who has spent his life farming. And now, with his life turned upside down he was ready to turn that passion into a full-time career.

Jeffery’s dad Jeff Garland had grown corn, soybeans and hay on a farm in Noblesville, Indiana for years before moving south to Crawford County. There, Jeff mostly focused on building wildlife habitat on the nearly 200 acres he owns, but he stayed connected to farming through a small vegetable operation on a few acres outside his home with a single small high tunnel.

But by March 2020 he was considering selling the farm before Jeffery called and suggested they start growing hemp. It had been legalized federally, Indiana had just started issuing growing licenses and from his time living in Colorado and developing content for a major hemp producer, Jeffery had built contacts he could lean on to get them started.

While the process of growing hemp was unfamiliar to Jeff, the final CBD based products derived from hemp’s oil were not. A severe car accident had left him hampered by multiple medical issues, but even after 13 surgeries and ongoing complications that impacted his quality of life, he was hesitant to use opioid based medications. He’d watched too many people who had been negatively impacted by opioids. So instead, Jeff turned to CBD products.

Starting the hemp farm with Jeffery would mean they would have full control over the products Jeff relies on daily and the ability to ensure their quality. It would also mean his son moving home to Indiana and getting to spend more time with Jeffery, his wife and their young daughter.

“I thought, if this stuff works, why not grow it myself and grow it organically,†Jeff said. “That way, I know what I’m putting in my body and what I’m producing and how it’s going to be used. So, it was a win-win for me.â€

The start-up costs were substantial due to the need to source mother plants and seeds, but the Garlands were committed to making it work. Jeff took charge of getting the necessary permissions and on his second round of application was approved for an Indiana hemp license. Jeffery, who was still based in Colorado at the time, worked to source their initial crop from contacts he’d made through his content business.

They identified a few different varieties they thought would flourish in Indiana’s climate and Jeffery began cultivating them while preparing to move to Indiana.

Papa G’s Organic Hemp was officially started in time for the 2020 growing season when Jeff and Jeffery drove their initial mother plants from Colorado to Indiana and started planting in Jeff’s former vegetable field outside his house.

Outwardly, the cannabis plants used to produce hemp oil are nearly identical to those used to produce marijuana. What differs is the internal chemistry. While marijuana plants are bred to produce the maximum amount of the psychoactive compound THC, hemp plants can be bred to maximize the non-psychoactive compound CBD, which is known for its medicinal uses, and can also be bred for fiber and grain products. Cannabis plants are required to remain below 0.3% THC to be considered hemp. Any higher levels and it is considered to be marijuana. The strict regulation creates a constant balancing act for growers such as the Garlands to maximize the lifespan of their crop while keeping it from going “hot.â€

“You go hot with a hemp crop, you just lost your whole season maybe,†Jeff said. “A hemp grower has a lot on the line opposed to a cannabis grower. A cannabis grower, he hopes it goes hot, as hot as he can get it. Whereas I have to watch it and check it every week.â€

The goal for hemp growers like the Garlands is to take the plant as close to “full-term†as they can without letting it go hot. That requires managing many of the environmental factors that can stress the plant including temperature, wind and the amount of water it receives.

That first season they grew a small portion in Jeff’s existing high tunnel but most of their crop was cultivated in an open field which gave them very little control. At the end of the season, they tested the quality of the plants and the ones grown in the high tunnel had well-outperformed the ones in the field. They had grown longer and larger, which led to more oil being produced, and the oil itself was a better quality.

With that data in hand, they began looking for ways to add an additional high tunnel prior to their second growing season. That search led them to USDA’s Natural Resources Conservation Service (NRCS) and the Environmental Quality Incentives Program (EQIP). Jeff already had a preexisting relationship with NRCS from enrolling 81 acres of the property surrounding his house into the Conservation Reserve Program (CRP). That program combines financial assistance from the Farm Service Agency (FSA) with technical assistance from NRCS and provided Jeff with an annual payment on the acres in order to establish permanent wildlife habitat.

Jeff then heard from a vegetable grower that NRCS has a program available to assist with the building of high tunnels on small and urban farms, much like the Garlands’ budding hemp farm. They applied for an EQIP contract in 2021 and were approved with construction on the tunnel slated to take place in time for the 2022 growing season. Not content to wait, the Garlands self-financed a tunnel prior to the 2021 season and then utilized the EQIP contract to build an additional one giving them three in all.

“We’ll have to pull early (in the field). Two to three weeks earlier in the field than we do in a high tunnel,†Jeff said. “When you let them go longer, you’re going to produce more oil. It’s important to have that high tunnel.â€

Because of the ability to control the growing environment for their plants, the high tunnels enable the Garlands to extend their season by multiple weeks on both sides. It a major part of turning their hemp operation into a truly year-round operation. They plant in early spring and keep the plants growing as far into the fall as they can, before immediately starting to prepare for the next season.

While they do start some plants from seeds, the vast majority of their plants each growing season are propagated as clones from mother plants they keep alive year-round. As the growing season ends, they move the mother plants into their climate-controlled propagation room where they are kept alive throughout the winter before being cloned in January to create the 4-5,000 plants they’ll use the next season.

As the plants are going through their propagation and then growing cycle, the Garlands are constantly working to make sure they stay within acceptable limits in terms of internal chemistry and not getting stressed to the point where they start pollinating. A major factor in that is controlling the inputs the plants receive and ensuring they have the nutrients they need to survive and flourish.

It is through that process where Jeffery’s mad scientist side comes out. The plants are nourished with a mix of teas, fermented solutions and organic materials such as worm casings and mushroom compost to create healthy “physically alive†soils and, in turn, healthy plants while staying within the bounds of their certified organic practices.

“It all starts with the soil,†Jeffery said. “If you don’t have good soil, you’re not going to have good plants and then you’re not going to have the best oil. So, we really put lots and lots of organic matter back into our soil.â€

Although they had already introduced multiple forms of compost and fertilizer to build the soil organic matter, the Garlands wanted to go further so they turned to NRCS for technical advice and worked with their local district conservationist Lee Schnell to develop a cover crop plan.

“I had to do my own research on what kind of cover crops we needed to build mycorrhizae for the hemp to basically just stop erosion because of the tillage,†Schnell said. “The tillage is kind of a ‘have to’ case with this crop. We wanted to cut down erosion, we wanted to fix nitrogen, we wanted to build mycorrhiza and we wanted to increase the soil biology.â€

They came up with a diverse mix, which the Garlands added to, creating a 17 species mix in all. Despite the need to lightly till the ground the Garlands utilize a modified process of planting green into the cover crop stand in order to maximize its benefits. And despite starting over from near scratch with all new varieties of hemp plants for the 2022 season, it is working.

On a hot June day a few months after transplanting their new varieties, the air at the farm is thick with the scent of growing cannabis plants. The iconic shaped leaves have grown to dinner plate sized and the plants are well on their well to reaching their maximum height of over six feet tall. In time, the plants will be dried and taken for processing where they’ll be turned into salves, tinctures, gel tablets and more. It is all part of their commitment to making the best products possible to help people like Jeff.

“Each season we learn more and we do more experiments of what works and what didn’t work,†Jeffery said. “Here we are on our third season, and I honestly think this is going to be our most productive year. Our plants are super healthy and they’re just going to be monsters.â€